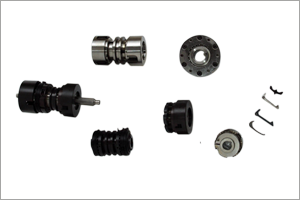

Mechanical Clutches are used in most engineering sectors such as machine tools, marine engineering, earth moving equipments and construction machinery depending on the requirements. The clutches are available for wet and dry running.

Types:

Mechanical Clutches are used in most engineering sectors such as machine tools, marine engineering, earth moving equipments and construction machinery depending on the requirements. The clutches are available for wet and dry running.

Types:

Using a mechanical clutch is the easiest and most cost-effective technique to engage a clutch.

There are two ways to use a mechanical clutch. It can be done by manually or with your feet. Mechanical clutches can be manually operated.

It can happen by means of levers, cams, or, in the case of bigger machinery, intricate linkages. This kind of task requires manual labor.

The lever or pedal usually needs to be positioned near to the clutch. This is for a mechanical clutch to be useful.

A locking mechanism is present in mechanical clutches. This device happens to maintain the system's connection.

It happens after the unit is engaged. The mechanism happens to stay engaged. It happens unless a force acting in the opposite direction disengages it.

Frictional forces provide the majority of mechanical clutches with their power. A moving component can synchronize with another moving component.

It happens at a different speed. This creates a stable connection for power transfer. This friction force is created by the driving and driven components interacting.

Achieve an optimal efficiency. It requires a minimum amount of slippage between the input and output shafts.

Mechanical clutches can have added functions to them. The device can be customized through the utilization of these functionalities. It is to fulfill specific requirements.

The main technique that Narsipur mechanical clutches are engaged and disengaged is through operator actuation.

It can be done with either hand or foot. The human element causes the maximal actuation force.

This is approximately 75 pounds. Many orders of magnitude more power is transferred by many huge devices than this. This is the result of the low engagement force.