- Home

- Products

Industrial Clutch Brake Suppliers

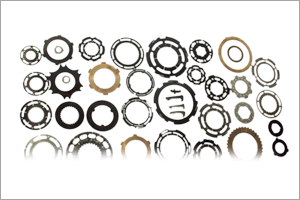

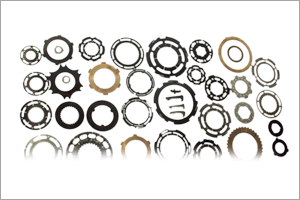

- All Type Of Clutch And Brake Plates

Clutch and Brake Plates

We also manufacture large quantity of clutch plates to a variety of customer specification and sizes. The Plates are supplied in three basic combinations.

We also manufacture large quantity of clutch plates to a variety of customer specification and sizes. The Plates are supplied in three basic combinations.

Steel / Steel

Steel / Sintered Lining

Steel / Organic Friction Lining

Our Plates are employed in a large variety of applications such as automatic or manual gearbox for highway vehicles, main drive boxes for tractors, winch drives, machine tool transmissions, marine reversing gears and general engineering.

We keep Most of the plates in stock.

Find the finest Industrial Clutch Brake Suppliers

The power transmission is engaged or disengaged by a clutch, a mechanical device. Additionally, it enables the controlled and seamless transfer of rotational power from a driven (machine) component to a driving (motor) component.

Use the cases for this type of technology. It happens to include those in which the driven devices start up and speed.

It also includes the operation need to be precisely regulated. Conveyor systems, pumps, and machine tools are just a few of the numerous equipment kinds. These can profit from these uses.

Select the appropriate clutch. It happens to be essential. It is essential for your machinery to function at its best. It is possible in terms of durability, dependability, and efficiency.

You will save money and time. It is as a result of needing to do less repairs and maintenance over time.

The Different Styles of Clutch Brakes

There are two primary types of clutch brakes. These you may use to significantly increase the efficiency of your machines and they are disc brakes and drum brakes.

A car's disc brakes are basically a metal disk.

It is been installed in the front wheel braking system. It is a robust pad. It contacts the brake disc to activate them.

This will cause a mechanism. It is to lose efficiency over time. It eventually stops working completely.

If longevity and dependability are important to you, disc brakes are a great choice. Compared to drum brakes, they are more effective and quieter. But the cost of them is exorbitant.

Your industrial gear may not always require the greatest brakes—there are times when a workhorse will suffice.

Drum brakes are an affordable, practical fix for large-scale machinery.

They might not be the most innovative choice, but they are still trustworthy.

Select a producer from the inventory.

After selecting between disc and drum brakes, the following step is to choose a reliable brake manufacturer.

You have the choice to make either or selection. The sheer number of industrial producers makes this appear like an overwhelming endeavor.

Narsipur works with the most reputable and superior industrial manufacturers in the world.

It is to provide you with the best machinery available.

You can find out more about the manufacturers they represent. You can find them by browsing online. For many manufacturers, they are authorized distributors.

FAQ'S

1. What are the industrial clutches and brake systems?

Industrial clutches and brakes are parts of machinery and equipment that allow power to be applied or motion to be stopped (brake) in order to control movement and stops.

2. In which sectors is usage of clutch and brake systems common?

Robot arms in heavy industries and automobile production lines have a assembled clutch and or brake system in them to aid in movement and the increase of safety.

3. What are invasive discs that clutch and brake systems use and where can they be purchased?

We provide a wide variety of friction, steel, and sintered plates for a vast range of industrial uses.

4. Why do people buy expensive plates for clutches and brake systems?

Purchasing quality plates help eliminate bumps in the system which usually makes the machinery work harder resulting in a lower lifespan for the piece of equipment.

5. Do your clients get custom made clutches and brake plates?

Yes, we give clients the ability to customize including but not limited to materials, size and performance of the needed parts.

6. How do you protect your clutches and brake plates from breaking under duress?

So we pass our plates through a host of international standard testing so they don’t break easily through load testing.

7. What materials are used in manufacturing clutch and brake plates?

Steel, cast iron, and various friction substances are used to manufacture clutch and brake plates, certifying the performance's credibility and quality.

8. What aspects to be taken in to account while selecting clutch and brake plates?

Among these factors are: the type of application; operating conditions; torque/dynamic requirement; material compatibility; and the ability to shed heat.

9. Do you provide after-sales support for your clutch and brake products?

Yes. Together with the products we sell, we also offer post-sale support including technical information, maintenance and servicing instructions, and troubleshooting assistance.

10. Where can I purchase clutch and brake plates from Indian Precision Engineers?

All the premium items we offer and for Clutch and Brake Plates, From Indian Precision Engineers you can order through the contact form or order a customized product by contacting us.

Looking for Clutch and Brake Plates?

We also manufacture large quantity of clutch plates to a variety of customer specification and sizes. The Plates are supplied in three basic combinations.

We also manufacture large quantity of clutch plates to a variety of customer specification and sizes. The Plates are supplied in three basic combinations.