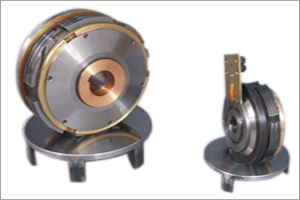

Multidisc clutches/brakes are known for their smooth acceleration... high operating performance. They are not surrounded by magnetic field. These type clutches are used with special friction material for the inner plates find use in dry applications also. The special feature of all our multi disc clutches/brakes are that the outer periphery of the outer plates are provided with finger springs which help in faster disengagement... minimal residual torque<

These Clutches / Brakes are being extensively used by original equipments machine tool manufacturers, SPM Builders, Printing and packaging industries, textile industries etc.

Electromagnetic multi-disc clutches are extensively used in the mountains automobiles industry today and they are known to deliver an extremely high amount of torque and that too in a comparatively smaller space.

The fact that these clutches can be used in both wet as well as dry systems makes them highly compatible and in demand.

The portion of the clutch that has a roter fitted can become magnetized and this sets up a loop. This further leads to the armature and the friction disc being attracted to it.

We are a large-scale electromagnetic multidisc clutch manufacturer in India and are proud to hold proficiency in manufacturing and supplying these components as well as many more.

We keep in mind all the industry standards and hence produce items that are in line with the latest technology and meet the growing needs of the competitive markets today.

We offer our services to all corners of the country and have ire wings spread far and wide.

These multi-disc clutches that we create are made by using some of the finest components and very high-quality unfinished raw material to meet the various demands of our clients.

With our huge market base and a wide range of clients, we have been able to find a strong footing in this specific area and can cater to all your breaks and clutches requirements at various levels.

You can check our product description by visiting the specific product category and getting every detail there. Everything from the type, finish to the material used is specified by us. For any further questions, you can contact our help desk and we will get back to you at the earliest.

We also customize these components for your specific needs and can provide you with the required quantity as per your need.

The main function of Brakes is to be able to hold the vehicle in place or deaccelerate the vehicle in the driving system. They are therefore an important constituent of the complete automation components.

Multi-disc breaks are one such type of brake that have certain specific functions in the working of a vehicle. They are mainly used as safety breaks and operated with the help of a spring.

These are mainly to operate in a situation where there might be a power failure and the vehicle may abruptly come to a stop. These breaks are beneficial in this situation because they have an extremely short span of engagement time.

These types of breaks mainly find usage in medical equipment and even have industrial use besides automobiles. They are able to hold the load very well in a given position and at a specific point of stoppage.

In order to integrate this in a more compact manner, the hollow shaft of the break is mounted onto an electrically driven motor.

The function of the Electromagnetic Multi-Disc Brake is such that the body made up of a magnet is mounted onto the machine when it is in a stationary state.

The brake is designed in a way that it ensures that the coil that is able to generate a magnetic field is not able to pass through the plates thereby leading to a quick response time.

We at Narsipurgroup are widescale Electromagnetic multi-disc brake manufacturers and have been in the business of manufacturing and supplying these components and many more for a long period of time.

We gave been active in providing an excellent and high quality of those components to various assembly units and manufacturing firms in the automobile industry as per their specific requirements.

These breaks that we offer are made with the most premium quality material that is of the standard value and caters to the high rising demands of the technology industry today.

| Torque Range | 25 Nm 2700 Nm |

| Voltage | 24 V.D.C |

Indian Precision Engineers stands tall among the other manufacturers of Electromagnetic Multi Disk Clutches in India due to their high-capacity industrial solutions.

Our multi-disc clutches are designed for efficiency, durability, and accuracy, making them a preferred choice among businesses in the automation, automotive, and heavy machinery sectors.

Electromagnetic Multi Disk Clutches are perfect for you. Their ability to operate at high speeds while engaging and disengaging mechanical systems makes them ideal for high power and high torque uses.

Material Handling Systems: Increases the efficiency of automatic machinery and conveyor systems.

Machine Tools: Enables effective work on drilling, milling, and grinding machines.

Here at Indian Precision Engineers, we manufacture electromagnetic multi disc clutches of the best quality. We have products that are tested for reliability to meet international standards and are ISO certified. We use the most current manufacturing methods alongside decades of experience.

Reach out to us today for more information regarding our products, and the innovative solutions we are known for. This is why Indians trust us as the Electromagnetic multi disc clutch manufacturers in India.