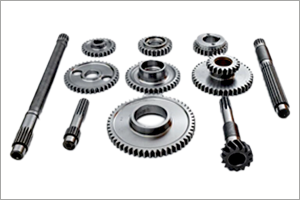

The Narsipur & Son’s Manufacturing Division’s range of Spur and Helical Gears, in hobbed, shaped or shaved conditions are specifically designed to cater to unique requirements of clients in the industrial and automotive field and used extensively for transmission, torque conversion, traction and speed control, direction of rotation and the translation of motion. The size range varies from 1 to 6 module with diameters ranging from 50 to 350 mm.

All auxiliary and prerequisite equipment necessary to manufacture gears like turning, grinding, broaching, etc. are available in-house to assist in manufacturing programs.

| Size range | 1 to 6 module |

| Diameter range | 50mm to 350mm |

Gears are mechanical devices that engage with other gears, a shaft, or groups of components to convey motion and torque or to initiate mechanical motion.

Using gears is an additional method of creating motion. Teeth are cut equally to enable gears to rotate in tandem and lock with each other.

Individual gears of various sizes and shapes can be connected together using teeth.

Gears benefit greatly from specific cutting techniques like gear hobbing since they can withstand the demands of continuous operation.

Manufacturers can modify shaft rotational speeds. This is for their specific requirements. It can be done by combining gears. It comes with various sizes.

Lubricating gears is a routine maintenance procedure. It increases their efficiency and lifespan.

Gears can produce amazing outcomes. It happens when properly maintained.

Gears are made from an extensive range of materials. Metals and sturdy polymers are the materials.

These are used most frequently. The automotive industry uses materials occasionally. This is Because of their extraordinary strength.

These are like copper, brass, steel, and even titanium. Gears are composed of some materials. These are like nylon or polycarbonate or plastic.

These all are resistant to water. These are used in lightweight machines frequently.

Manufacturers of industrial gears carefully consider the number of teeth and gear ratios while designing their products.

They make every effort to take into account all of the factors that could impact the gear's strength, speed, functionality, control within a larger assembly, and lifetime.

Using the previously mentioned production methods, Narsipur manufacturers can develop custom gears that are designed to meet the requirements of any application.

Industrial gearboxes are used by a lot of enterprises. It is to finish their processes. This is particularly true in many industries.

These industries are paper, sugar, cement, chemical, and rubber. Gearboxes are highly sought for in these industries.

These are small and flexible. Narsipur manufacturers are primarily focused on developing advanced equipment.

It enables businesses to operate more lucratively. It comes with lower energy expenses.